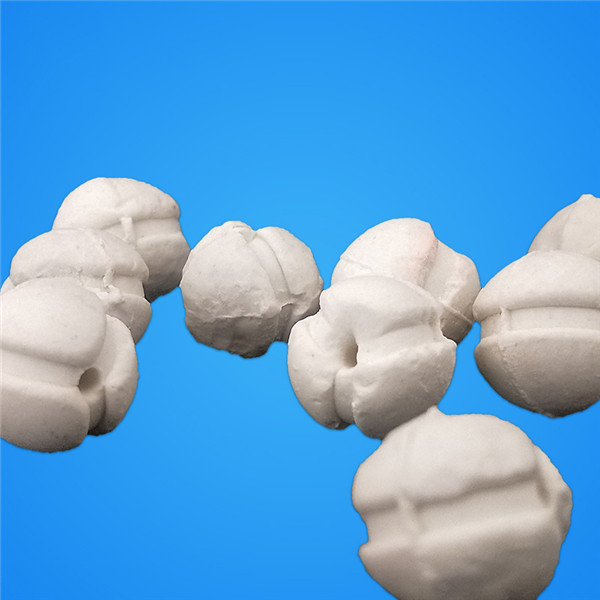

Porous yumbu Manufacturer ball daban-daban size

Aikace-aikace

Ƙwallon yumbu mai ƙuri'a sabon samfuri ne wanda aka haɓaka bisa tushen inert alumina yumbu ball. Yana ɗaukar diamita na ƙwallon a matsayin axis don buɗe ramin. Ba wai kawai yana da wasu ƙarfin injina ba, kwanciyar hankali na sinadarai da kwanciyar hankali na thermal, amma har ma yana ƙara takamaiman yanki. Kuma rabo mara kyau, ta haka yana haɓaka tarwatsawa da jujjuyawar kayan, da rage juriya na tsarin. Ana iya amfani da shi ko'ina a cikin masana'antar mai, sinadarai da iskar gas don maye gurbin ƙwallan yumbu na alumina mara amfani azaman mai kara kuzari wanda ke rufe kayan tallafi.

Abubuwan Jiki

| Nau'in | Feldspar | Feldspar - Molai | Molai Stone | Molai - Corundum | Corundum | |||||

| Abu | ||||||||||

| Abubuwan Kemikal | Farashin 2O3 | 20-30 | 30-45 | 45-70 | 70-90 | ≥90 | ||||

| Al2O3+ SiO2 | ≥90 | |||||||||

| Fe2O3 | ≤1 | |||||||||

| Adsorption na Ruwa (%) | ≤5 | |||||||||

| Resistance Acid (%) | ≥98 | |||||||||

| Alkaki Resistance (%) | ≥80 | ≥82 | ≥85 | ≥90 | ≥95 | |||||

| Yanayin Aiki (°C) | ≥ 1300 | ≥ 1400 | ≥ 1500 | ≥ 1600 | ≥ 1700 | |||||

| Ƙarfin Murƙushewa (N/Pice) | Φ3mm ku | ≥400 | ≥420 | ≥440 | ≥480 | ≥500 | ||||

| Φ6mm ku | ≥480 | ≥520 | ≥ 600 | ≥ 620 | ≥ 650 | |||||

| Φ8mm ku | ≥ 600 | ≥700 | ≥800 | ≥900 | ≥ 1000 | |||||

| Φ10mm | ≥ 1000 | ≥ 1100 | ≥ 1300 | ≥ 1500 | ≥1800 | |||||

| Φ13mm | ≥ 1500 | ≥ 1600 | ≥1800 | ≥2300 | ≥2600 | |||||

| Φ16mm | ≥1800 | ≥2000 | ≥2300 | ≥2800 | ≥3200 | |||||

| Φ20mm | ≥2500 | ≥2800 | ≥3200 | ≥3600 | ≥4000 | |||||

| Φ25mm | ≥3000 | ≥3200 | ≥3500 | ≥4000 | ≥4500 | |||||

| Φ30mm | ≥4000 | ≥4500 | ≥5000 | ≥5500 | ≥ 6000 | |||||

| Φ38mm | ≥ 6000 | ≥ 6500 | ≥7000 | ≥8500 | ≥ 10000 | |||||

| Φ50mm | ≥8000 | ≥8500 | ≥9000 | ≥ 10000 | ≥ 12000 | |||||

| Φ75mm | ≥ 10000 | ≥ 11000 | ≥ 12000 | ≥ 14000 | ≥ 15000 | |||||

| Yawan yawa (kg/m3) | 1100-1200 | 1200-1300 | 1300-1400 | 1400-1550 | ≥1550 | |||||

Girma da Haƙuri (mm)

| Diamita | 6/8/10 | 13/16/20/25 | 30/38/50 | 60/75 |

| Haƙuri na diamita | ± 1.0 | ± 1.5 | ± 2.0 | ± 3.0 |

| Pore diamita | 2-3 | 3-5 | 5-8 | 8-10 |